Fully ADA Compliant Truncated Dome Technology

Over 30 years of tactile design, testing, and manufacturing insights make Access® Tile’s detectable warning systems the superior product they are today. Access® Tile’s tactile walking surface indicators (TWSI) utilize wayfinding bar tiles, and truncated domes. Our truncated dome tile boasts the easiest and fastest installation in the industry, making it the perfect choice for projects which require cost-effective ADA compliant tiles. Our Replaceable Cast in Place ADA tiles are installed directly into wet set concrete, in only 5 minutes, and feature an industry leading replaceability feature. Every Replaceable Cast in Place tile can easily be cut on-site, without voiding the product warranty.

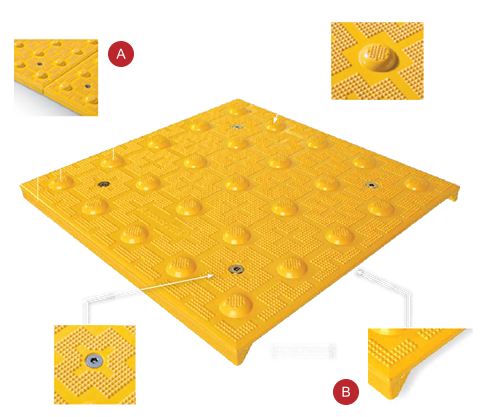

Tile geometry allows for consistent dome spacing between adjoining tiles.

High density, diamond grip™ pyramid micro texture designed for exceptional slip resistance in wet and dry conditions.

Nylon composite, corrosion resistant anchor and stainless-steel fastener provide unlimited re-installation due to self-threading design.

Strategically placed reinforcing internal ribs determined by Finite Element Analysis (FEA) generates enhanced stiffness and structural support.

Reinforced top and bottom flange determined by Finite Element Analysis (FEA) generates enhanced stiffness and structural support.

Hexagonal molded forms for permanent interface between tile and anchor system. Fastener/anchor system comes pre-assembled.

Access® Tile also offers our Replaceable Cast in Place tiles as Radius Curve tiles, and Wayfinding tiles.

Applications for Access® Tile Replaceable Cast in Place Tiles

All our Replaceable Cast in Place detectable warning tile products are designed to be ADA compliant, allowing persons of every ability to navigate your space safely. The wayfinding bar tiles help guide the public through your space, and the truncated dome installations act to alert the public when they reach the path’s end. Access® Tile’s Replaceable Cast in Place truncated dome tile is used worldwide for municipal pedestrian crossings and curbs, serving to warn the public when they reach an unsafe edge. Our truncated dome technology is especially useful for individuals with visual impairments as the raised domes can be felt comfortably through footwear. Every detectable warning paver is available in bright colors, such as federal yellow and brick red, allowing some persons with visual impairments to see the warning tiles. All of our ADA compliant tiles are designed with a unique sound reflection technology. This feature enables individuals who use guidance canes to navigate your space unaided; by tapping their cane, they can audibly hear the difference between a walkway and one of our ADA warning tiles.

Frequent applications of Access® Tile’s Replaceable Cast in Place Tiles include:

- ADA Curb Ramps

- Accessible Pedestrian Crossings

- Vehicular Passage Ways

- Parking Areas Made To Be ADA Compliant

- Safe Escalator Approaches

- Tops and Bottoms of Stair Landings

- ADA standard Wheelchair Ramps

- Accessible Transit Platforms

- Multi-Modal Transit Stations

Intelligent Design Features of our Replaceable Cast in Place Tiles

Access® Tile’s expert construction makes us the industry leader in affordable detectable warning tile. Our Replaceable Cast in Place tiles install in minutes and feature our industry-leading replaceability innovation. These tiles are the choice of developers worldwide, as they are quick and straightforward to install and replace. The ease of installation gives you more time to focus on other aspects of your project. Multiple detectable warning tiles can be anchored together using our tamper-proof stainless-steel fasteners, which maintain a flush interface with tactile walking surface indicators.

Each tactile walking surface indicator (TWSI) is corrosion resistant, slip resistant, and abrasion resistant. Our Replaceable Cast in Place tiles are tested rigorously to ensure they sustain dynamic vehicle loading, using the AASHTO HS20-44 wheel load test. All truncated domes are further tested against wear and tear, to ensure the longevity of your detectable warning surface. Multiple anchors are placed on each ADA tile to provide maximum strength and support. Our ADA compliant tiles are specifically designed to be affordable yet long-lasting, exceeding the needs of any project.

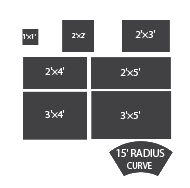

Our Replaceable Cast in Place tiles are the most affordable tile in the industry and are available in a variety of homogeneous colors and sizes.

Available colors include Orchre Yellow (23594), Federal Yellow (33538), Safety Red (31350), Colonial Red (20109), Brick Red (22144), Ocean Blue (15187), Pearl White (27925), Dark Grey (36118), and Onyx Black (17038).

Our tiles can easily be cut on-site to conform to the unique angles or radius ramps, providing a project-specific ADA compliant solution.

Access® Tile’s Detectable Warning Tiles exceed the requirements of all projects and codes.

Available Sizes

Available Colors

FED 23594

FED 33538 / RAL 1003

FED 31350

FED 20109 / RAL 8012

FED 22144 / RAL 3016

FED 15187 / RAL 2486

FED 27925

FED 36118 / RAL 2486

FED 17038 / RAL 9005

To determine the number of Replaceable Cast in Place tiles needed for your projects, use our free Radius Curve Calculator.

Our Replaceable Cast in Place detectable warning tiles feature an intelligent design and come with many built-in benefits, such as:

- Installs in minutes during the finishing stage of wet set concrete

- The replaceability feature of the tile is industry leading, due to its simplicity and speed

- Tamper-proof, stainless-steel screw maintains a flush interface with the walking surface

- Multiple Nylon anchor locations ensure complete integration of tactile surface with concrete

- Interactive sizes – all tiles maintain pattern repeat when mounted side-to-side or top-to-bottom

Installation & Replacement Information For Access® Tile Cast in Place TWSI

Access® Tile’s Replaceable Cast in Place ADA tiles are manufactured to be lightweight, versatile and extremely easy to handle. Our ADA compliant tiles are designed to install or replace with ease; this particular tile can be set directly into fresh concrete. A complete installation package is available with each order of Access® Tile’s Replaceable Cast in Place truncated dome tile.

For quick reference, please see our installation and replacement instructions below:

Installation Instructions:

- Maintaining a 4–7 slump range, pour and float

the concrete. - Without removing any concrete, place the tile on

the curb ramp 6″–8″ from the curb line (face of curb). - Tamp the tile in a grid pattern across the top

face, embedding the tile into the concrete using a non-marring rubber mallet. - Create a 1/4″ concrete free edge around the

perimeter of the tile using a 3/8″ radius edging tool then float the concrete

around the tile’s perimeter using a steel trowel. - Apply a broom-finish to the curb ramp.

- After the concrete has substantially cured,

remove the protective plastic wrap by cutting the plastic with a sharp knife

tight to the concrete/tile interface.

Replacement Instructions

- Unscrew T27 tamper-proof fasteners.

- Tap perimeter of tile with a rubber mallet to

remove bond of tile to concrete. - Use a pry bar to pry up an edge. Remove all

debris from vacant cavity mold. Vacuum/sweep all crevices. - Insert replacement tile, gently apply pressure

to seat tile in recess. Reinsert tamper-proof fasteners in hex shape concrete

anchors.

Installation Guide

Replacement Guide

State and Federal Code Compliance

- 2.35″ center-to-center, in-line dome spacing

meets ADA federal and state requirements - Truncated dome size, and spacing compliant with

ADA federal and state requirements, 0.9″ base and, 0.45″ top diameter - Fully complies with all ADA and OSHA

requirements for surface height transitions to eliminate trip hazards - Consistent dome spacing when tiles are adjoined

(side-by-side or end-to-end) - Wide in-line dome configuration facilitates a

smooth rolling transition for strollers, wheelchairs, and walkers - Integral UV stable homogeneous color throughout

truncated dome surface

All Access® Tile products fully comply with the Americans with Disabilities Act (ADA), Public Right-of-Way (PROW), and California Title 24 Requirements. For more information, please see the official Truncated Domes ADA Requirements.

ASTM & UL Tests for Cast in Place TWSI

All our detectable warning pavers undergo rigorous testing including ASTM concrete tests, and ASTM D tests.

- Tensile Strength ASTM D638

- Flexural Strength ASTM D790

- Compressive Strength ASTM D695

- Accelerated Weathering ASTM G155

- Slip Resistance ASTM C1028

- Flame Spread Index ASTM E84

- Accelerated Aging (

freeze thaw ) ASTM D1037 - Linear thermal Expansion ASTM D696-03

- Tile Bond Strength ASTM C1583